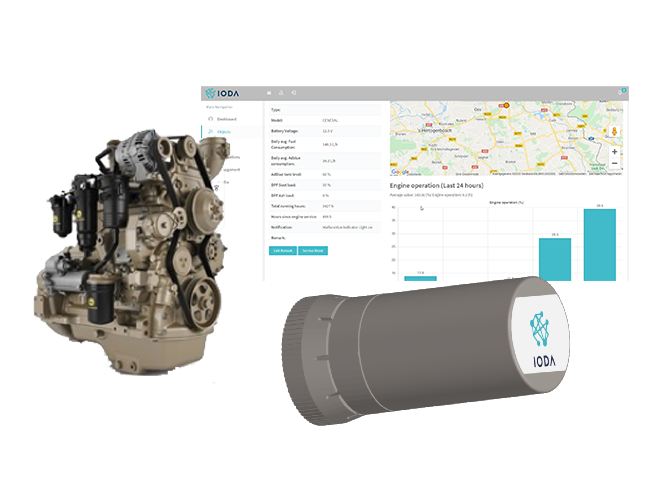

Remote engine IoT monitoring solution

Monitor engines and machines in any sector including marine, industry, forestry, agriculture and construction. Transform products into services: improve engines reliability and increase customer satisfaction.

Key engine parameters monitoring

Cellular connectivity for global coverage

Clear web application with actionable insights